Opaque White Enamels

Fire at 1450°F (780ºC) for 2½ minutes.

LOW ACID RESISTANCE

1006. This is a low acid resistance enamel which is used as the base coat for the crackle technique, in combination with Liquid Form Water Base enamels.

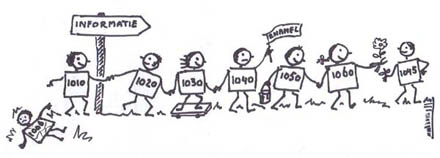

1010 - (Formerly sold as 621-A) It is unique in having a high softening point as well as a high expansion. This makes it an ideal base coat for other enamels, especially transparents. It has good opacity, excellent gloss and surface. Can be used as a regular white where acid resistance is not required.

HIGH ACID RESISTANCE

1020. A super opaque titania white with excellent covering power, gloss and surface. This is the white used for our white steel panels. Excellent one coat or two coat white for areas to be left white. Since its expansion is on the low side, only thin coats of other colours should be applied over this white when used on copper. It has good acid resistance. It can also be used for the crackle technique.

1030. This white has medium opacity. It is slightly translucent. It can be used as an undercoat and is acid resistant. When finely ground it is suitable to be used in the grisaille and camaieu techniques.

1040. This white is less opaque than 1030. It is translucent. It can be used as an undercoat and is acid resistant. It can be used over 1010 to obtain a surface with more 'depth'. When finely ground it is suitable to be used in the grisaille technique, but will require more applications to build up white than the 1030.

1045. This white was developed for bead making. Normally used in 6-20 mesh, this white does not reduce or grey in a propane flame.

1050. This mat enamel fires as a normal transparent. It glosses on the first firing and will grow mat white crystals. With longer or more firings it will texture greatly.

1060. This white is very opaque and was developed for the commercial badge making industry.